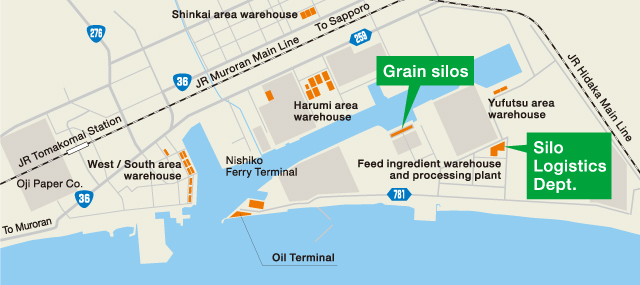

Silo Logistics Department

We support Hokkaido’s stockbreeding industry with the highest class grain silos and facilities in northern Japan.

Supporting the stockbreeding industry in Hokkaido

Hokkaido consumes up to 3.6 million tons of feed ingredients per year, with corn, barley, oats, soybean meal, grass, etc. imported from countries like the United States, Canada, and Australia. Approximately one-third of the feed ingredients are supplied to feed mills throughout Hokkaido via our facilities and play an important role in supporting the livestock industry of Hokkaido.

Achieving stable supply with an advanced system and the largest-scale facility in Hokkaido

Most of the feed ingredients, imported by large vessels from all over the world, are handled in cargo handling facilities with a capacity of up to 1800 tons/h, then stored in grain silos with a capacity of 190,150 tons, and warehouses with a capacity of 33,583 m². Warehouse entry/dispatch management is carried out in a command room with advanced IT-enhanced functions. Our staff utilizes their abundant expertise and experience to provide safe and efficient services.

Meeting customer needs with various distribution processing functions

The needs for feed ingredients distribution processing have been diversifying. To meet these needs, we have grinding and pelletizing facilities, automatic bagging facilities, and bonded warehouse. With our experienced staff operating, we can provide customers with one-stop, high-quality logistics services.

Thorough safety management of feed ingredients

For businesses involved in the distribution of feed ingredients, the first priority is “to transport products pest-free.” Feed ingredients that are safely stored and managed at our silo facilities in compliance with the Feed Safety Law are directly supplied to its adjacent feed manufacturing plant by conveyors. By installing large-scale vehicle disinfection equipment that sterilizes the entire truck at both the entrance and the exit, we strive for thorough safety management.

Facility Overview

Cargo handling equipment

- Unloaders:

- 4 units

300t/h x2 units, 400t/h ×1 unit, 800t/h ×1 unit (mechanical type)

- Truck unloading facilities:

- 4 lines

100t/h ×1 line, 300t/h ×1 line, 330t/h ×1 line, 400t/h ×1 line

- Container unloading equipment:

- 1 line

100t/h

Storage equipment

- Grain silos:

- 302 units

190,150t *302 bonded silos

(Main silos: 176 units, 156,420t; additional silos: 102 units, 28,930t; soybean meal silos: 24 units, 4,800t)

- Feed ingredient warehouse and processing plants:

- 8 bldgs.

33,583㎡ *5 bonded warehouses

Shipping equipment

- Feed mill delivery:

- 5 lines

main/additional raw materials 120t/h, soybean meal 50t/h

- Truck loading:

- 13 lines

main/additional raw materials 100t/h, soybean meal 80t/h

- Domestic vessel loading:

- 1 line

240t/h

Logistics processing equipment

- Feed ingredient milling facilities:

- 3 units

7t/h ×1 unit, 20t/h ×1 unit, 50t/h ×1 unit

- Pellet processing facility:

- 1 unit

10t/h

- Automatic bagging equipment:

- 2 lines

240 bags/h ×1 line, 600 bags/h ×1 line